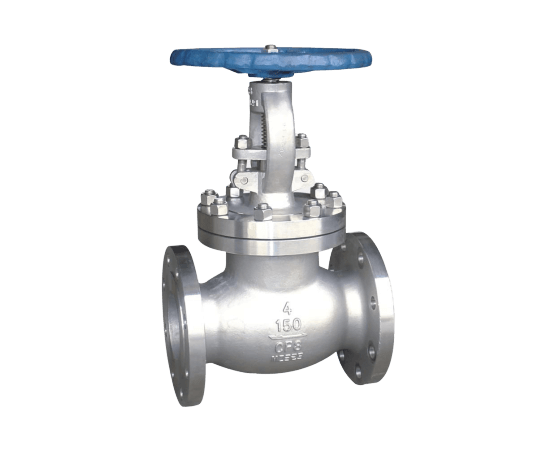

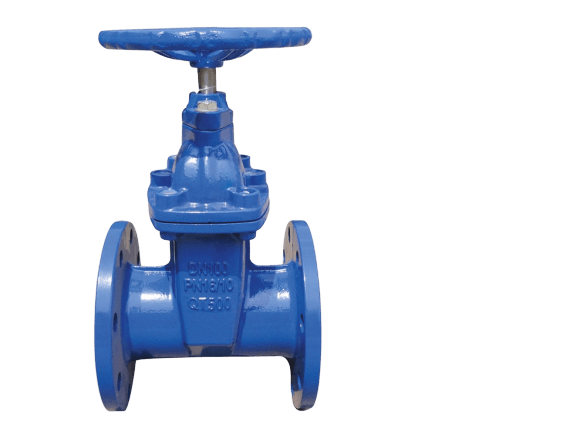

Gate Valve

Gate valves are widely used across many industries, commonly for wastewater and liquid gas. They are used primarily to cut off a pipeline when the sealing surface of the ram and valve seat is smooth and even. By relying on the top mold, spring, or ram, they can also prevent mediums from flowing through each other.

Product Description

Gate valves, as their name suggests, use a gate mechanism to open and close a valve. The gate moves perpendicularly to the direction of the medium. It cannot be adjusted or throttled, but only fully opened or fully closed. The gate has two sealing surfaces; the most commonly used gate valves form a wedge shape. The wedge angle varies with the valve parameters, usually 5,° and 2,° when the medium temperature is not high. The gate of the valve can be made into a whole; this configuration is called a rigid gate. Additionally, it can be made into a gate that can produce a small amount of deformation to improve its processability and make up for the deviation of the sealing surface angle during processing; this configuration is called a spring gate.

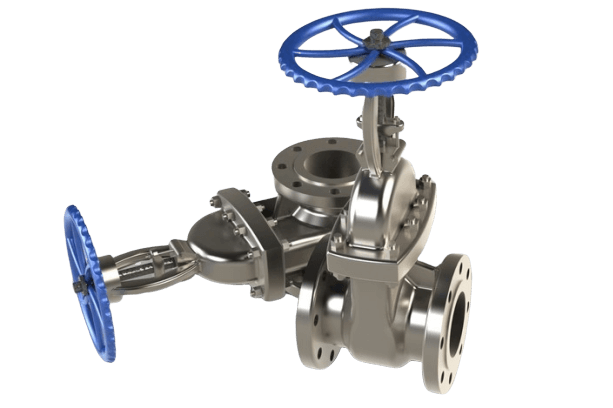

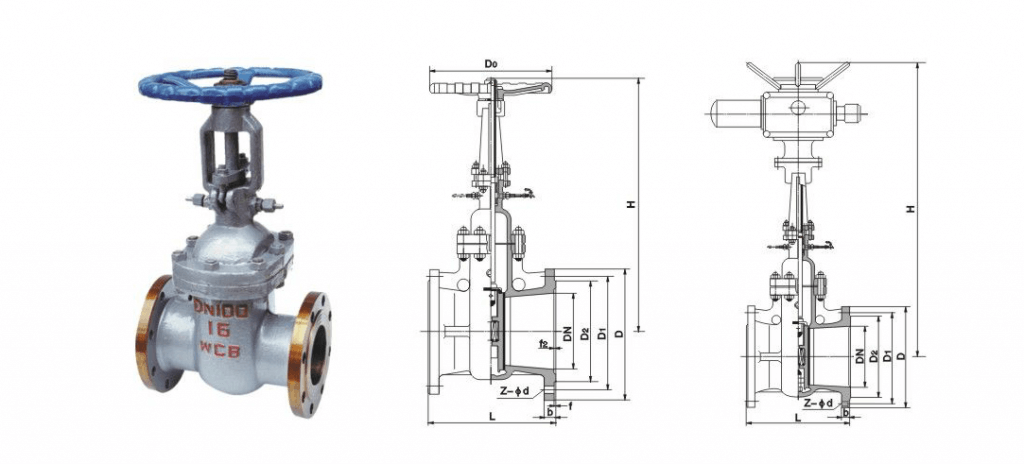

When the gate valve is closed, it can only be sealed by medium pressure, that is, the sealing surface of the gate is pressed against the valve seat on the other side with medium pressure to ensure the self-sealing of the sealing surface. Most gate valves are forcedly sealed; when the valve is closed, the gate is forced against the valve seat externally to ensure the tightness of the sealing surface. The gate of the valve then moves linearly with the valve stem and is called a lift lever gate or open lever gate valve. Usually, there is a trapezoidal thread on the lifting rod and the rotary motion changes to linear motion through the nut on the top of the valve and the guide groove on the valve body. Here, the operating torque changes to the operating thrust. When the valve is opened, the lift height of the gate is equal to 1:1 of the valve diameter. The fluid channel is completely clear; this position, however, cannot be monitored during operation. In actual use, the apex of the valve stem is used as a mark, which means it cannot be put into a fully open position. In to address the lock-up phenomenon caused by changes in temperature, it is usually opened to the top position, and then back to 1 / 2-1 circle as the position of the fully open valve. Therefore, the fully open position of the valve is determined by the position of the shutter or stroke. In some gate valve models, the stem nut is set on the gate plate. The hand heel then rotates to drive the valve stem to rotate, and the gate plate is raised.

Product Structure

Product Features

Product Parameters

- Low flow resistance- the medium channel inside the valve body is straight, forcing medium to flow in a straight line, creating low resistance.

- The reduced effort required to open and close- the direction of movement of the shutter is perpendicular to the direction of medium flow when compared with the shut-off valve, whether it is open or closed.

- High height, long opening and closing time- the opening and closing stroke of the shutter is large, and the lifting is performed by a screw.

- The water hammer phenomenon is not easy to produce, the reason being the long shutdown time.

- Gate valve channels are symmetrical on both sides, meaning the medium can flow in any direction, making installation simple.

- Small, compact structure length (distance between the two connecting end faces of the shell), simple shape, lightweight design, and wide application range.

- Strong valve rigidity and smooth media passage

- Stainless steel and hard alloy sealing surface, ensuring reliable sealing, extended life, and PTFE packing.

| Design Spec | GB/T 12234 |

| Face to Face | GB/T 12221 |

| Flanged End | JB/T 79 |

| Test & Check | JB/T 9313 |

| Pressure-Temp | GB/T 9131 |

| Marking | GB/T 12220 |

Valve Selection Guide

Export Ball Valve, Knife Gate Valve, Ceramic Valve, Gate Valve

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- Reliable Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.

FAQ

Guarantee

Q1: What is your product range?

A: Our range of centrifugal pumps includes slurry pumps, gravel pumps, clean water pumps, sewage pumps, and chemical pumps, both as whole pumps and spares.

Q2: What’s your MOQ?

A: Our MOQ for a centrifugal pump is 1 set.

Q3: What are your accepted forms of payment?

A: T/T, L/C, Western Union, and PayPal.

Q4: How long is your lead time?

A: In general, lead times are seven working days for a slurry pump,15 working days for a water pump, and seven working days for pump spares.

Q5: What information I need to offer a quotation?

A: Liquid:___ ; Pump Capacity___m3/h ; PH:_____ ; Pump Head: ___m ; Specific of gravity___ ; Voltage ___V ; Frequency ___Hz

Q6: Are OEM

parts available?

A: Yes. Please send a detailed drawing.

We are so confident in the quality of our pump and pump spares that we offer one of the only 100% free test and trial in the market.

We offer a free trial- if you are not satisfied after trying our Warman type pumps and spares, call us at +86 3125060076, and we will work with you to address your concerns.

If no resolution can be reached, simply return us the product, and we will refund your money, minus the shipping charges.