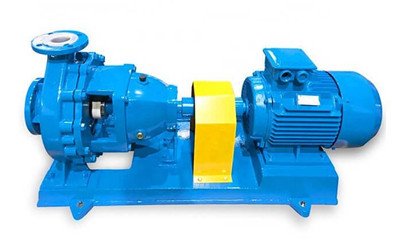

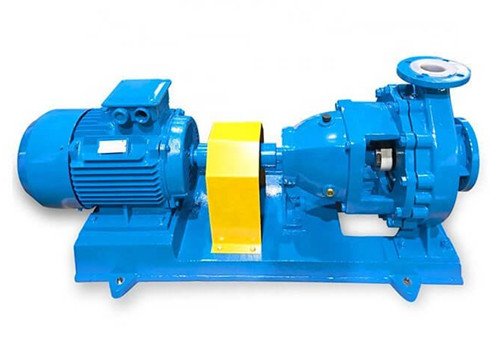

ZA Chemical Process Pump

Product Description

This series of chemical process pump is an updated replacement. It is based on the American National Standards Institute’s ANSIB731M standard and combined with advanced pump manufacturing experience now. The super versatile and interchangeable design not only reduces spare parts storage and management costs but also reduces the overall operating cost of the pump, which makes it a new alternative across the general chemical industry by its unique durability, reliability, and economy.

No leakage is the eternal pursuit of chemical equipment.

1. For static seals, there are usually only two types of gaskets and seals, and O-rings are the most widely used seals. For dynamic seals, chemical pumps rarely use packing seals, mainly mechanical seals. Mechanical seals are divided into single and double end faces, balanced type and unbalanced type. The balanced type is suitable for high-pressure medium sealing (usually refers to a pressure greater than 1.0MPa). Double-end mechanical seals are mainly used for high temperature, easy to crystallize, and have viscosity. For media containing particles and toxic volatiles, double-end mechanical seals should inject isolation fluid into the sealed cavity. The pressure is generally higher than the medium pressure by 0.07 ~ 0.1MPa.

2. Sealing. The chemical process pump static sealing material generally uses fluoroelastomers. In special cases, PTFE is used. The material configuration of the dynamic and static ring of the mechanical seal is more critical. It is not that cemented carbide is the best. On the one hand, it is not reasonable for the two to have no hardness difference, so it is best to treat them differently according to the characteristics of the medium.

Product Features

Main Application

The seal cavity of the chemical process pump cover is designed as an inverted cone and is provided with a flow guiding block, which can reduce the pressure in the sealed chamber and keep the impurities in the medium away from the seal, so as to minimize the erosion of impurities on the seal.

The impeller adopts a back-open structure, and it is easy to adjust the gap between the impeller and pump cover.

Thin-oil is used to lubricate bearings. There are splashing discs to increase lubrication and cooling effect and constant oil cup to ensure sufficient lubrication.

The rotor is provided with an axial adjustment mechanism, which can allow adjusting the gap between the impeller and the pump cover from outside accurately without removing the pump, thereby it can achieve the purpose of adjusting the performance of the process pump and greatly simplify the maintenance process.

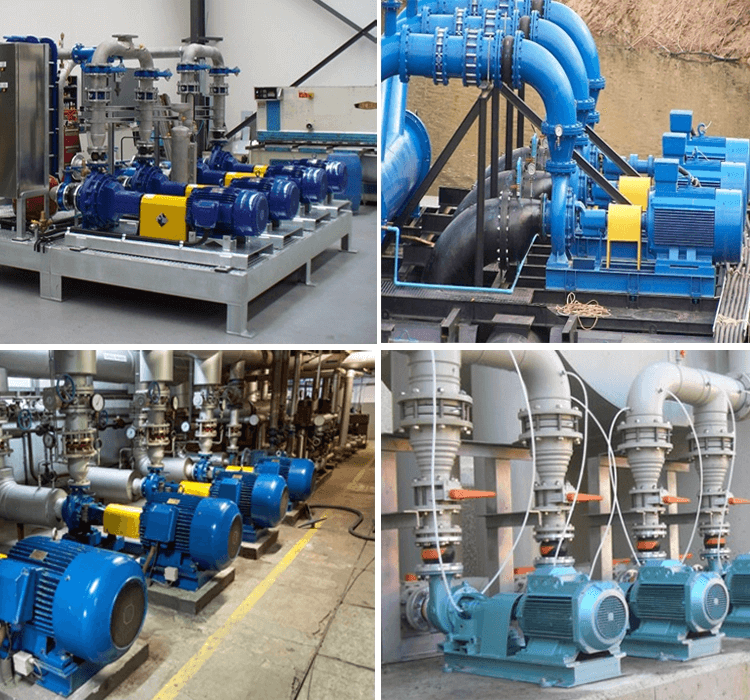

This series of chemical process pump is mainly used in chemical, petrochemical, refinery coal chemical, power plant, paper, pharmaceutical, sugar, steel, waste acid treatment, water supply, and drainage urban water supply, food deep processing and other industries.

The Main Parameters

| Horsepower | 10-1000hp |

| Maximum Flow Rate | 6.3-400m3/h |

| Maximum Head | 5-125m |

Chemical Process Pump Live Application

Pump Selection Guide

Export Slurry Pump,Chemical Process Pump,Vertical Slurry Pump,Sand Pump

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- Reliable Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.

FAQ

Guarantee

Q1: What is your product range?

A: Our range of centrifugal pumps includes slurry pumps, gravel pumps, clean water pumps, sewage pumps, and chemical pumps, both as whole pumps and spares.

Q2: What’s your MOQ?

A: Our MOQ for a centrifugal pump is 1 set.

Q3: What are your accepted forms of payment?

A: T/T, L/C, Western Union, and PayPal.

Q4: How long is your lead time?

A: In general, lead times are seven working days for a slurry pump,15 working days for a water pump, and seven working days for pump spares.

Q5: What information I need to offer a quotation?

A: Liquid:___ ; Pump Capacity___m3/h ; PH:_____ ; Pump Head: ___m ; Specific of gravity___ ; Voltage ___V ; Frequency ___Hz

Q6: Are OEM

parts available?

A: Yes. Please send a detailed drawing.

We are so confident in the quality of our pump and pump spares that we offer one of the only 100% free test and trial in the market.

We offer a free trial- if you are not satisfied after trying our Warman type pumps and spares, call us at +86 3125060076, and we will work with you to address your concerns.

If no resolution can be reached, simply return us the product, and we will refund your money, minus the shipping charges.