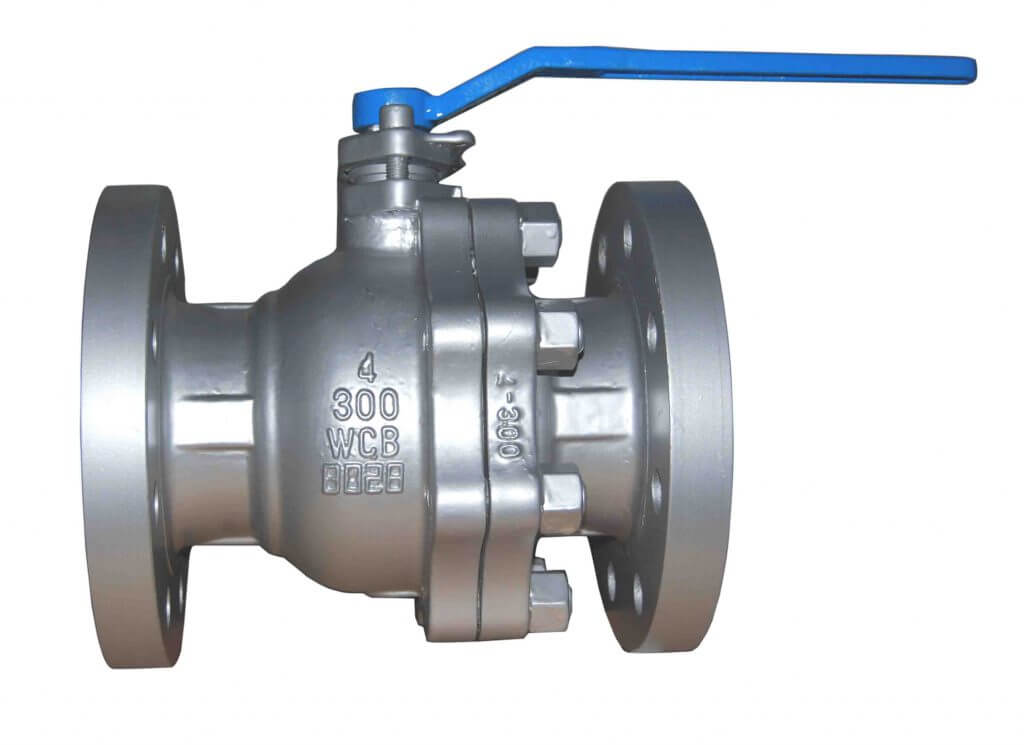

Ball Valve

Ball valves employ the use of a ball driven by a stem to regulate and control the flow of fluids. The stem rotates around the axis of the ball valve, and is generally in the “open position” when in use. The hard-sealed V-ball valve has a strong shear force between the V-shaped core and the metal valve seat of the hardfacing. Ball valves are exceptionally useful in settings where fast, secure sealing is needed, especially for media like gasses, small fibers and small solid particles, provided it does not create regular wear on the port that can decrease its effectiveness. This is why they are in high demand in the oil, natural gas, and chemical The multi-way ball valve can not only flexibly control the confluence, divergence and flow direction of the medium on the pipeline, but also can close any channel and connect the other two channels. This type of valve should generally be installed horizontally in the pipeline. Ball valves are generally categorized by the driving mode used, and categories include pneumatic ball, electric ball, and manual ball valves. Pneumatic ball valves involve a piston or diaphragm to provide power to move the valve stem. Electric ball valves use an actuator powered by electrical source. Manual ball valves involve a lever used by a human operator to turn the control on and off. Benefits of ball valves include minimal maintenance, compact size, no need for lubrication, a tight seal, and is among the most cost-effective options.

Product Description

Our ball valve model has low fluid resistance, saves energy by opening and closing, and can be used when the medium flows in two directions. The sealing surface is not easily eroded when fully opened, and is highly resilient, and its short structure length is suitable for both large and small valves.

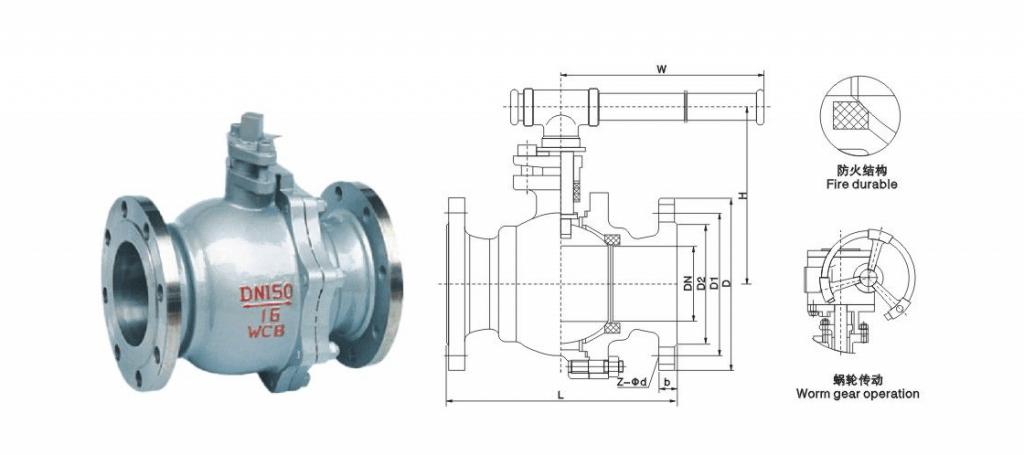

Product Structure

Product Features

- Low fluid resistance- its resistance coefficient is equal to the pipe section of the same length.

- Small, lightweight, simple structure.

- Tight reliable seal; has been widely used in vacuum systems.

- Easy to operate- fast opening and closing. Rotate 90° from fully open to fully closed, making remote control convenient.

- Easy maintenance- seal ring is usually movable for convenient disassembly and replacement.

- Wide application range, from small several millimeter to large several meter diameters; high vacuum or high pressure can be applied.

Product Parameters

| Temperature Pressure Class | According to ASME B16.34 |

| Wall Thickness of Valve | ASME B16.34 |

| Flow Hole Size | API6D |

| Face-to-Face Dimension | ASME B16.10 |

| Welding End Size | ASME B16.25 |

| Body Material Selection Options | A105, Lf2, Lf3, F304, F316 |

Valve Selection Guide

Export Ball Valve, Knife Gate Valve, Ceramic Valve, Gate Valve

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- Reliable Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback, and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ an in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same, and that different jobs require different tools- that is why we take pride in the fact that are well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.

FAQ

Guarantee

Q1: What is your product range?

A: Our range of centrifugal pumps includes slurry pumps, gravel pumps, clean water pumps, sewage pumps, and chemical pumps, both as whole pumps and spares, and valves

Q2: What’s your MOQ?

A: Our MOQ for a centrifugal pump is 1 set.

Q3: What are your accepted forms of payment?

A: T/T, L/C, Western Union, and PayPal.

Q4: How long is your lead time?

A: In general, lead times are seven working days for a slurry pump,15 working days for a water pump, and seven working days for pump spares.

Q5: What information I need to offer a quotation?

A: Liquid:___ ; Pump Capacity___m3/h ; PH:_____ ; Pump Head: ___m ; Specific of gravity___ ; Voltage ___V ; Frequency ___Hz

Q6: Are OEM

parts available?

A: Yes. Please send a detailed drawing.

We are so confident in the quality of our pump and pump spares that we offer one of the only 100% free test and trial in the market.

We offer a free trial- if you are not satisfied after trying our Warman type pumps and spares, call us at +86 3125060076, and we will work with you to address your concerns.

If no resolution can be reached, simply return us the product, and we will refund your money, minus the shipping charges.