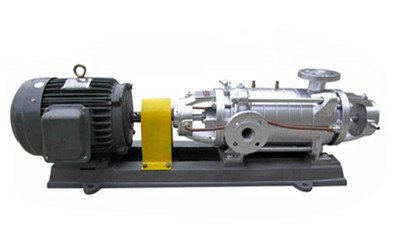

D、DG Multistage Pump

Product Description

This series of multistage booster pump has a sub-horizontal, multi-stage, single-suction, and centrifugal flow design, and employs state-recommended hydro module technology. This multistage pump is composed of four parts, including the stator, rotor, bearing, and shaft seal. Here, we will discuss each part in detail.

- The stator is comprised of the suction section, the middle section, the discharge section, and the guide vanes. Each section is clamped by a tightening bolt to form a working room. D-type pumps generally suck horizontally and spit upwards vertically; when used for oilfield water injection, the pump inlets and outlets are oriented vertically and upwards. The outlet and inlet of the DG multistage pump are also oriented vertically and upward.

- The rotor is composed of the shaft, impeller, balance disk, and shaft sleeve. The axial force is balanced by a balance disc.

- The multistage pump bearings are composed of bearing bodies, bearings, and bearing glands. The bearings are lubricated with grease or thin oil.

- The shaft seal employs a soft packing seal, composed of a sealed box, packing, and water retaining ring on the water inlet section and the tail cover. The D-type model water seal water comes from the pressure of the water in the pump; the DG model water seal water comes from an external water supply.

- The multistage pump is driven directly by the prime mover through the elastic coupling. Looking at the pump from the end of the prime mover, the pump rotates clockwise. The D and DG models are horizontal, single-suction, multistage, segmented centrifugal pumps.

Product Features

Main Application

- The unique structure and attractive appearance

- Rust-resistant, fully sealed shaft structure, preventing contact with mediums

- Packing seal and mechanical seals are safe, reliable, simply designed, and convenient to maintain

- Low noise

- Advanced hydraulic model, high efficiency, wide performance range

- Suitable for transporting clean water (impurity content of less than 1%; the granularity of less than 0. 1mm) and/or other liquids with similar physical and chemical properties.

- The D/DG multistage pump model is suitable for transportation of mediums with temperatures no greater than 80˚C, including mine discharge and water feeding to factories and cities.

- The D/DG multistage pump is suitable for transportation of mediums with temperatures no greater than 105˚C, water being fed to a small boiler, or similar applications.

- Oilfield water injection pumps use different materials, depending on the corrosive nature of the medium. The temperature of the DG pump must be less than 120 ˚C, which is suitable for various boiler feed water.

The Main Parameters

| Flux | 6.3~450 m³/h |

| Lift | 75~685 m |

| Motor Power | 5.5~1050kw |

| Product Standard | JB/T1051-93 |

Multistage Pump Live Application

Pump Selection Guide

Export Slurry Pump,Chemical Pump,Vertical Slurry Pump,Sand Pump

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- Reliable Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.

FAQ

Guarantee

Q1: What is your product range?

A: Our range of centrifugal pumps includes slurry pumps, gravel pumps, clean water pumps, sewage pumps, and chemical pumps, both as whole pumps and spares.

Q2: What’s your MOQ?

A: Our MOQ for a centrifugal pump is 1 set.

Q3: What are your accepted forms of payment?

A: T/T, L/C, Western Union, and PayPal.

Q4: How long is your lead time?

A: In general, lead times are seven working days for a slurry pump,15 working days for a water pump, and seven working days for pump spares.

Q5: What information I need to offer a quotation?

A: Liquid:___ ; Pump Capacity___m3/h ; PH:_____ ; Pump Head: ___m ; Specific of gravity___ ; Voltage ___V ; Frequency ___Hz

Q6: Are OEM

parts available?

A: Yes. Please send a detailed drawing.

We are so confident in the quality of our pump and pump spares that we offer one of the only 100% free test and trial in the market.

We offer a free trial- if you are not satisfied after trying our Warman type pumps and spares, call us at +86 3125060076, and we will work with you to address your concerns.

If no resolution can be reached, simply return us the product, and we will refund your money, minus the shipping charges.